Our identity

Saguenay Foundry is a North American Leader that produces sand Iron castings and is ready to place its solid expertise in metallurgy to your service. The quality of the parts is supervised by professional Engineers and our customer care is second to none. The company is managed by its owners thus providing a solid commitment to its long-term relationships for customers in North America and around the world.

With 3D sand printing, our own CNC wood & Styrofoam pattern shop, Saguenay Foundry is in a position to reduce both production and total cost, have reduced process times while still providing quality castings with the shortest lead times possible. We also developed a strong expertise in managing customer spare part inventory programs so you can better service your customers needing legacy parts.

Our strong commitment to innovation requires that we continually invest in our foundry to maintain our technical expertise and our peek operational performance. You also benefit from our uncompromising QA system certified through ISO 9001:2015 standard, our 3D design capabilities and the most up-to-date mold flow analysis software version to ensure superior molding and pouring of ductile, gray and CGI iron castings.

FORERUNNER IN THE FOUNDRY WORLD

Saguenay Foundry is also a precursor in environmentally friendly foundry processes improvements. In the 1980’s, Saguenay Foundry replaced its coal melting furnaces with a cleaner energy high-efficiency electric induction melting equipment. In 2002, we moved to furanic sand binders which besides improving casting finish quality, has the added bonus of being recyclable. The procurement of recycled metal as our base material for producing castings is another action taken to lower our environmental impact.

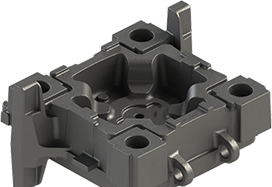

Larges parts

made to order

What distinguishes us from the competition is a highly qualified staff working with the most advanced technology available in CAD, Mould flow simulation softwares and 3D printing and robotics. From orders requiring fast prototyping to several hundred parts annually, we promise on-time delivery of quality ductile, gray and CGI alloy castings weighing from 200 to 16,000 pounds. ( 90 kg to 7,250 kg ).

See our portfolioRequest a Quote

Poured Weight Per part

| Materials | Minimum (lbs) | Maximum (lbs) |

|---|---|---|

| Grey iron | 200 | 16000 |

| Ductile iron | 200 | 16000 |

| Compacted Graphite iron | 200 | 16000 |

| Steel | 3000 | |

| Stainless steel | 3000 | |

| Aluminium | 500 | |

| Magnesium | 300 |

Please fill in the spaces and attach your required files such as drawings and specification charts. A Fusium expert will send you a quotation in the fastest time possible.