Fusium and aeronautic

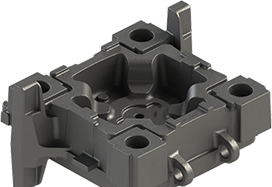

At Fusium, we understand how important it is to obtain robust, long-lasting parts. And we also know that the aviation sector has implemented the highest standards of safety and quality control. That’s why we pay special attention to each of our manufacturing steps.

Why work with Fusium

Fusium listens to your needs and allows you to select the short or medium runs that correspond to your specific needs.

Typical production

runs

From prototyping up to 1,000 pieces.

Support

Fusium masters the various production stages which makes it possible to obtain parts with no defects, as required for aeronautics applications. X-rays, precise assembly of complex molds and validations with state-of-the-art devices such as programmable CMMs, are second nature at Fusium.

Request a Quote

Poured Weight Per part

| Materials | Minimum (lbs) | Maximum (lbs) |

|---|---|---|

| Grey iron | 200 | 16000 |

| Ductile iron | 200 | 16000 |

| Compacted Graphite iron | 200 | 16000 |

| Steel | 3000 | |

| Stainless steel | 3000 | |

| Aluminium | 500 | |

| Magnesium | 300 |

Please fill in the spaces and attach your required files such as drawings and specification charts. A Fusium expert will send you a quotation in the fastest time possible.