We know your challenges

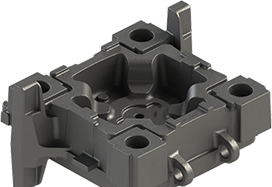

Because choosing the right parts is a key step in any metal processing project, we pay special attention to the manufacturing phase in order to create robust, efficient parts at an optimal cost.

Why work with Fusium

Our professionals have the experience required to provide you with first-rate services. At Fusium, you’ll be able to find the high-quality, durable parts needed for metal processing.

Typical production

runs

From prototyping up to 1,000 pieces.

Support

To ensure continuity of operations for these customers, Fusium can manufacture complex parts in just a few days due to its great operating flexibility which can be adapted rapidly. Also, an inventory system adapted to the realities of the metal processing industry is put in place in each factory to provide for all emergencies. The Saguenay Foundry team has the technical competencies and experience to solve problems arising from contact of these parts to liquid metal.

Request a Quote

Poured Weight Per part

| Materials | Minimum (lbs) | Maximum (lbs) |

|---|---|---|

| Grey iron | 200 | 16000 |

| Ductile iron | 200 | 16000 |

| Compacted Graphite iron | 200 | 16000 |

| Steel | 3000 | |

| Stainless steel | 3000 | |

| Aluminium | 500 | |

| Magnesium | 300 |

Please fill in the spaces and attach your required files such as drawings and specification charts. A Fusium expert will send you a quotation in the fastest time possible.