Mining industry challenges

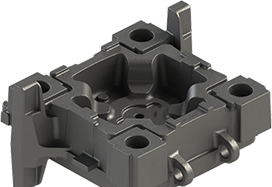

Because you need to depend on your tools, our manufacturing processes are stringent and allow us to create robust components that are incredibly resistant, durable, and efficient.

Why work with Fusium

We’re ready to meet your needs and understand your mining industry projects. We’re committed to providing outstanding service and to manufacturing only the best parts.

Typical production

runs

From prototyping up to 1,000 pieces.

Support

To ensure the reliability of castings produced by Fusium, they are subjected to a plethora of tests such as ultrasound, magnetic particle inspection, tensile tests, and any other relevant examination all of which are carried out directly at the foundry. Complete reports are then sent to the customer to allow him to release the part and allow it to be sent to the mining site.

Request a Quote

Poured Weight Per part

| Materials | Minimum (lbs) | Maximum (lbs) |

|---|---|---|

| Grey iron | 200 | 16000 |

| Ductile iron | 200 | 16000 |

| Compacted Graphite iron | 200 | 16000 |

| Steel | 3000 | |

| Stainless steel | 3000 | |

| Aluminium | 500 | |

| Magnesium | 300 |

Please fill in the spaces and attach your required files such as drawings and specification charts. A Fusium expert will send you a quotation in the fastest time possible.