Fusium and pump industry

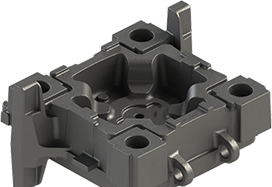

Pumps are complex parts that are often produced from intricate drawings and plans. The process requires an outstanding expertise because these components are often put under great strain. That’s why we use superior manufacturing processes and tools to ensure a robust, long-lasting product.

Why work with Fusium

Our detail-oriented team pays special attention to your needs and we will leverage our know-how to provide pumps adapted to your projects.

Typical production

runs

From prototyping up to 1,000 pieces.

Support

Fusium knows how to adapt its production according to the industry served. In the case of pumps, special attention is given to ensure the integrity of the walls to prevent leakage. In addition, our ability to manufacture styrofoam or 3D printing molds significantly reduces cost when replacing pumps that have been in service for years and for which the original patterns have often been destroyed.

Request a Quote

Poured Weight Per part

| Materials | Minimum (lbs) | Maximum (lbs) |

|---|---|---|

| Grey iron | 200 | 16000 |

| Ductile iron | 200 | 16000 |

| Compacted Graphite iron | 200 | 16000 |

| Steel | 3000 | |

| Stainless steel | 3000 | |

| Aluminium | 500 | |

| Magnesium | 300 |

Please fill in the spaces and attach your required files such as drawings and specification charts. A Fusium expert will send you a quotation in the fastest time possible.